Troubleshooting Sewing Machine Thread Tension Problems

Learn how to fix sewing machine tension and more with our sewing machine troubleshooting guide.

You are so ready to sew, but when you put the pedal to the metal on your sewing machine something is not quite right.

Your sewing machine tension is clearly not where it should be. Maybe one thread is too tight or another is just hanging loosely. These problems are the most frustrating sewing machine problems.

Plus, fixing sewing machine tension problems can be daunting!

Adjusting all those settings? What if something goes wrong? Opening up your machine? Forget about it! Never fear, the editors at AllFreeSewing are here to help!

This page, Troubleshooting Sewing Machine Thread Tension Problems, goes over how to fix sewing machine tension involving not only thread but other features of your sewing machine.

With images and details to help you rethread and check your machine, you'll be ready to tackle your issues. Not to mention that we're also including additional resources to help you with other sewing problems you might run into.

Just scroll down and read this guide on sewing machine tension repair and get the quick fixes you need before doing anything that might make things worse.

Join Our Sewing It Up Newsletter for More Help and Free Patterns >>>

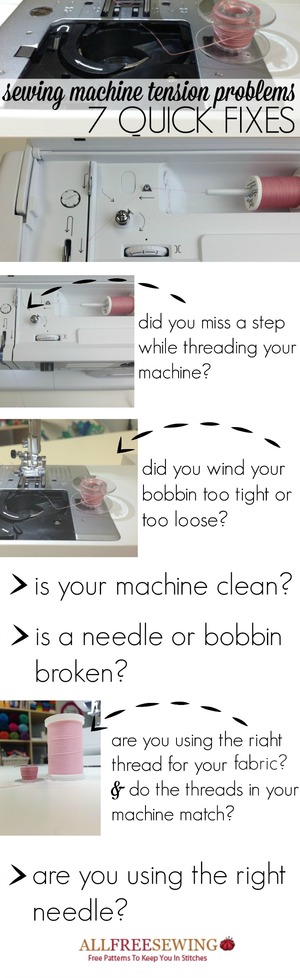

Sewing Machine Thread Tension Problems: Quick Fixes

Before doing anything to your machine, you need to go through this checklist. You might not even having sewing machine tension problems! Something else might be going wrong.

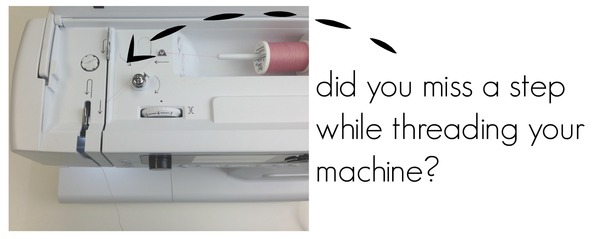

- Rethread your machine: If there’s any glitch or hiccup with your threading, your machine might not work properly.

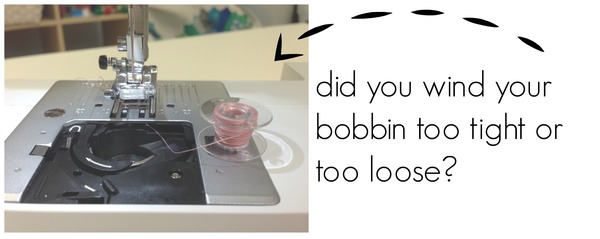

- Check your bobbin: Try a new bobbin or try rethreading your bobbin. A loose or too-tight bobbin can cause your sewing machine tension problems.

- Clean your sewing machine: A dusty or dirty machine can hinder the thread moving through your machine easily. Make sure there are no dust bunnies in the way!

- Check for broken parts: A bent needle or broken bobbin can easily cause your machine to malfunction. Be sure to insure that these parts are in tip-top shape before adjusting the tension or doing anything else!

- Check your thread: Make sure you are using the right thread for the fabric you are using! The wrong thread can cause sewing machine tension problems.

- Compare your threads: Having two different types of thread in your machine can cause tension problems as your machine might have a harder time pulling one through. Try to use the exact same thread (or at least the same type if you want two colors).

- Check your needle too: Too big or too small of a needle can make your fabric pucker stretch incorrectly. Be sure to look up which size needle to use with your chosen fabric.

You can also save or pin this image below if needed!

PLUS! Beginner Sewing Resources

If you're a beginner, then you'll want to take a look at these helpful pages. Everything below is going to help you master basic techniques, speed up your processes, and get you on the right track for becoming a masterful sewist.

- How to Use a Seam Ripper

- How to Use a Thimble

- Sewing Tools & Equipment

- What Types of Thread to Use

- How to Cover Up Sewing Mistakes

- Machine Paper Practice Sheets

- How to Stop Fraying on Fabric

- Are Sewing Machines Easy to Use?

- What is Sewing Machine Oil?

- How to Use a Sewing Machine

- How Do You Clean a Sewing Machine?

- How Do You Thread a Sewing Machine?

- Ultimate FAQs Guide

- Glossary of Sewing Terms

Want More?

What is a Serger Machine?

Now that you have solutions for sewing machine thread tension problems, what other problems have you had with your sewing machine?

Let us know in the comments!

Read Next50+ Sewing Crafts That Sell Well

Your Recently Viewed Projects

msbaby 9729906

Apr 02, 2021

Excellent article. But I would add that presser-foot selection may solve problems. I'm working with a very lightweight crepe with an unusual finish, and found that a teflon non-stick foot totally solved the problem.

Lynn K

Nov 21, 2018

This is not only a great tutorial for beginners but also a really good reminder for me so thank you! Also I never realised that the wrong size needle could cause tension problems so that is something I will look out for in future as well as all the other possible causes explained above.

Weberme

Dec 30, 2016

These are some great tips to follow and I have experienced all of them before the most is the threads being to different weights. It is hard to remember if you used a new spool of thread or existing one when you did bobbin and had not used that color in awhile so now that is the first thing I check. Most of the time it is the thread not threaded properly or wrong size needle. This is a must watch tutorial to read for a beginner to get familiar with sewing. You will be glad you did. This is well worth your time to read.

lauralou2 9782606

Sep 19, 2015

Thank you for all your tips.I'm slowly getting back into sewing

foofinster 3666252

Oct 19, 2014

Also, the spool is put in wrong. The spool should be put on the machine so it spins as thread is unwinding. If you have a thread cone then it stands up and thread comes off the top.

Report Inappropriate Comment

Are you sure you would like to report this comment? It will be flagged for our moderators to take action.

Thank you for taking the time to improve the content on our site.